Eccentric Wedge Insert for oil field

Series:Insert for oil field

Workpiece:oil field

Keywords:

Insert for coal mining

Category:

Product Description

Tungsten carbide button are a widely used tool in the mining industry, essential to help extract and break rocks. They are produced using high-quality material and advanced technology, ensuring their durability and high performance. As a manufacturer in China, we offer high-quality Carbide Mining Buttons to merchants all over the world at a competitive price.

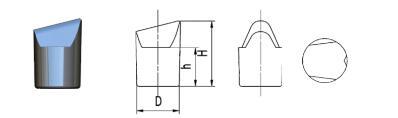

Engineering mining alloy teeth have high wear resistance and impact toughness. It has a variety of full-size tooth shapes, including spherical insert, conical insert, parabolic insert, eccentric wedge insert etc.

Our advantage of making tungsten carbide button bits is that we are using HIP sintering for minimizing the porosity of carbide blank for increasing the transverse ruputure strenth (TRS). It is very suitable for high quality requirment for making carbide bottons to be ued in high and medium pressure DTH Drilling. As its unique working performance, tungsten carbide button bits are widely applied to oil filed drilling and snow removal, snow plough machines or equipments.

Tungsten carbide button characteristics

1. Cemented carbide/tungsten/spherical button

2. Wearing resistance good

3. Best suited to hard rock

4. Abrasive to very abrasive

Application:

Carbide Buttons are made from Tungsten carbide powder and cobalt powder, it has very high hardness, toughness and were resistance, wildly used in mining, excavating and construction tools. DTH drill bits industry need huge quantity carbide buttons, which are pressed into face and side of the DTH bits head.

Material introduction:

| Grade |

Density (g/cm3) |

Hardness HRA |

TRS (Mpa) |

Applications recommended |

| HK603 | 13.95 | 85.5 | 2700 |

The insert that the open head is higher and the profile is complicated.The pressure on drill is higher.The rock formation is ultra hard and complicated |

| HK453 | 14.2 | 86.0 | 2800 |

Both of the height of open head of insert and the drilling pressure are in the middle.For drilling the mid-hard or hard rock formation |

| HK353 | 14.2 | 87.5 | 3000 |

The insert that the open head is shorter and the profile is simpler.2.For drilling the mid-hard o close to soft rock formation |

| HK602 | 13.95 | 86.8 | 3000 | The insert that the open head is higher and the profile is complicated.The pressure on drill is bigger.Applied to the ultra hard and complicated rock formation 4.Its wear resistance is higher than KD603 |

| HK452 | 14.2 | 87.5 | 3000 | Both of the height of open head of insert and the drilling pressure are in the middle. Applied to drill the mid-hard or hard rock formation.lts wear resistance is higher than KD453 |

| HK352C | 14.2 | 87.8 | 3000 |

The Insert that the open head is shorter and the profile is simple.2.For drilling the mid-hard or closetosoftrockformation.3.Its wear resistance is higher than KD353 |

| HK302 | 14.5 | 88.6 | 3000 |

For use in the drills of the shorter open head and simple profile of insert and lower drilling pressure.Applied to drill hard rock formation or nonferrous metals mine |

| HK202M | 14.7 | 89.5 | 2600 | For use as diameter keep insert.Back insert,and serrate insert |

Size for spherical: ( can be produced according to the size and shape required by the customer)

| Type | Dimension | ||

| Diameter | Height | Cylinder Height | |

| HS0911-E13 | 9.4 | 11.8 | 6.8 |

| HS1112-E19 | 11.4 | 12.5 | 6.0 |

| HS1114-E23 | 11.3 | 14.5 | 7.9 |

| HS1418-E20 | 14.2 | 18.0 | 9.9 |

| HS1217-F12Q | 12.2 | 17.00 | 10.0 |

| HS1420-F15Q | 14.2 | 20.0 | 11.8 |

| HS1624-F15Q | 16.3 | 24.0 | 14.2 |

Related Products