Carbide brazed insert

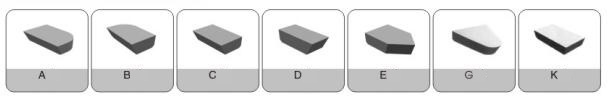

Series:A, B, C, D, E, G, K

work-piece: Steel, Stainless steel, Carst iron

Keywords:

Insert for coal mining

Category:

Product Description

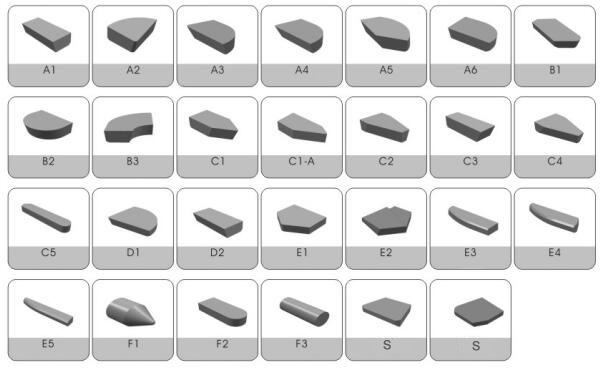

China's national standard for carbide brazed insert:

Tolerances of L, T and S ( China's national standard )

| Dimensions | Tolerances | Tolerances of L for typed E1 & E2 | |

| Tolerance Plus | Tolerance Minus | ||

|

≤ 6 |

±0.2 |

+0.3 | -0.1 |

| >6-12 | ±0.3 | +0.4 | -0.2 |

| >12-25 | ±0.4 | +0.6 | -0.3 |

| >25-40 | ±0.6 | +0.8 | -0.4 |

| >40 | ±0.7 | +0.1 | -0.4 |

International standard for carbide brazed insert:

Tolerances of L, T and S ( International national standard )

| Dimension |

≤6 |

>6-12 | >12-25 | >25-50 | >50 |

| Tolerances |

+0.3 0 |

+0.4 0 |

+0.6 0 |

+1.0 0 |

+2.0 0 |

| Grade |

Density g/cm3 |

Bending strength ≥N/mm2 |

Hardness ≥HRA |

Recommended application |

| YG3X | 15-15.4 | 1180 | 91.5 | Suitable for finishing of cast iron and non-ferrous metals |

| YG3 | 15-15.4 | 1180 | 90.5 | |

| YG6X | 14.8-15.1 | 1420 | 91 | Suitable for finishing and semi-finishing of cast iron and non-ferrous metals, also can be used for processing manganese steel &quenched steel |

| YG6A | 14.7-15.1 | 1370 | 91.5 | |

| YG6 | 14.7-15.1 | 1520 | 89.5 | Suitable for semi-finishing and roughing of cast iron and light alloy, and can also be used for roughing of cast iron and low alloy steel |

| YG8N | 14.5-14.9 | 1500 | 89.5 | |

| YG8 | 14.6-14.9 | 1670 | 89 | |

| YW1 | 12.7-13.5 | 1180 | 91.5 | Suitable for fininshing and semi-finishing of stainless steel and ordinary alloy steel |

| YW2 | 12.5-13.2 | 1350 | 90.5 | Suitable for semi-finishing of stainless steel & low alloy steel |

| YS8 | 13.9--14.2 | 1620 | 92.5 | suitable for the finishing of iron - and nickel-based superalloys with high strength. |

| YT5 | 12.5-13.2 | 1430 | 89.5 | Suitable for heavy cutting of steel and cast iron. |

| YT15 | 11.1-11.6 | 1180 | 91 | Suitable for finishing and semi-finishing for steel and cast iron. |

| YT14 | 11.2-11.8 | 1270 | 90.5 | Suitable for finishing and semi-finishing for steel & cast iron; Milling processing for YS25 special steel and cast iron. |

| YS25 | 12.8-13.2 | 1620 | 90.5 | |

| YS30 | 12.4 | 1715 | 91 | |

| YC45 | 12.5-12.9 | 2000 | 90 | Suitable for heavy cutting tools, and has good effect on rough surface turning of castings and various steel forgings. |

| YS2T | 14.3-14.6 | 1800 | 91.5 | Suitable for low-speed turning, milling of heat-resistant alloys and titanium alloys, especially for cutting to and tapping. |

Welding steps:

1. Check the blade thoroughly

◆ Check the blade surface for cracks and other defects

◆ Remove burrs from alloy sheet

◆ If there is an oxide layer on the surface, first use green silicon carbide grinding wheel to remove the oxide layer of the welded surface.

2. Choice of flux

◆ Choose the right flux

◆ Use flux to clean rust, grease, etc., clean the tool bar

◆ The flux can prevent the oxidation of the tool rod and alloy sheet caused by heating

3. Soaking heat and slow cooling

◆ The bottom of the tool bar should be heated first when welding (for oxygen welding)

◆ Soaking heat to prevent hot cracking

◆ Do not overheat. The welding temperature is reached when the solder alloy melts and can flow freely. Overheating will burn the solder and cause oxidation.

4. Remove the adhesive at the welding part of the alloy sheet. During the welding process, the blade should be gently moved to remove the adhesive at the welding part

◆ The blade and insert should be carefully wet and filled with solder

5. Cool gently

◆ After welding, carbide cutting tools shall not be quenched in water, otherwise it will crack the carbide blade

◆ Precision cutting tools are not allowed to cool in the air

◆ If there is a risk of cracking due to welding stress, the tool should be placed in an incubator after welding and heated to 200-250 degrees for 6-8 hours

Related Products