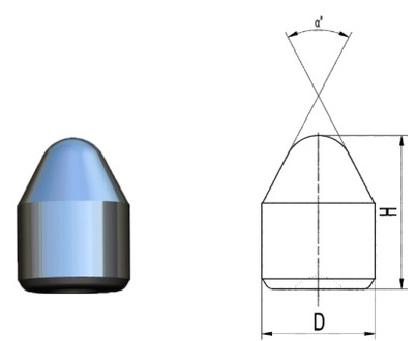

Conical Insert for mining

Series:Insert for mining

Workpiece:mining

Keywords:

Insert for coal mining

Category:

Product Description

Engineering mining alloy teeth have high wear resistance and impact toughness. It has a variety of full-size tooth shapes, including spherical insert, conical insert, parabolic insert, eccentric wedge insert etc.

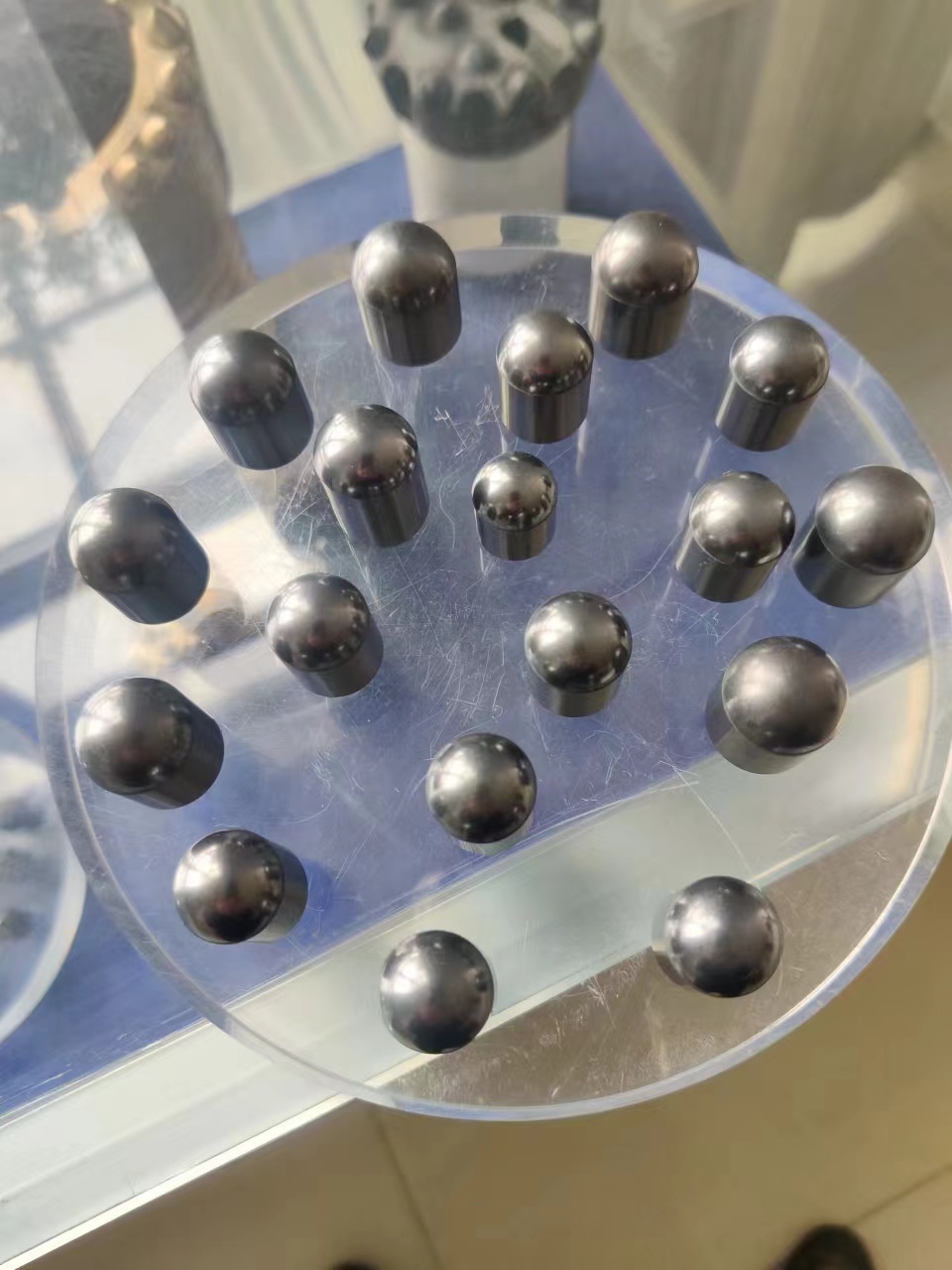

Tungsten Carbide Buttons for DTH Bits – the ultimate solution for drill bits. Made from the toughest tungsten carbide material, these buttons are designed for superior performance and durability, making them perfect for the most challenging drilling applications.

Tungsten Carbide Buttons for DTH Bits are widely used in drilling, mining, construction, and other industries. They come in various sizes and shapes, allowing you to choose the right buttons for your needs. Our buttons are also available as inserts, which can be easily fitted into drill bits to maximize their performance.

Tungsten carbide button characteristics

1. Cemented carbide/tungsten/spherical button

2. Wearing resistance good

3. Best suited to hard rock

4. Abrasive to very abrasive

Tungsten carbide button application

As its unique working performance, tungsten carbide buttons are widely applied to oil filed drilling and snow removal, snow plough machines or equipments. Cemented carbide buttons are used in the coal cutter drilling tools, mine machinery tools and road maintenance tools for snow clearing and road cleaning. Carbide mining button bits are widely applied for rock tools, mining tools for use in quarrying, mining, tunneling, and civil constructions.

Material introduction:

| Grade |

Density (g/cm3) |

Hardness HRA |

TRS (Mpa) |

Applications recommended |

| HK102 | 14.95 | 90.2 | 2800 | Engineering, coal, mining, suitable for general rock formation under a lower pressure |

| HK102C | 14.95 | 90.5 | 2800 | Engineering, coal, mining, suitable for general rock formation under a lower pressure. wear resistance better than HK102 |

| HK102T | 14.95 | 90.5 | 3000 | For hard and ultra hard rock formation under high pressure. Can be used for hydraulic pressure helical drill. |

| HK132T | 14.92 | 90.2 | 3200 | For hard and ultra hard rock formation under high pressure. Can be used for hydraulic pressure helical drill. Impact resistance is better than HK102T |

| HK323 | 14.41 | 87 | 2900 | Applied to mount on the inhole drill with bigger diameter to drill mid-hard and hard rock formation. |

Size for spherical: ( can be produced according to the size and shape required by the customer)

| Type | Dimension | ||

| Diameter | Height | Angle | |

| HZ0812 | 8.2 | 12.2 | 58 |

| HZ1015 | 10.2 | 15.2 | 55 |

| HZ1217 | 12.2 | 17.2 | 55 |

| HZ1318 | 13.2 | 18.2 | 55 |

| HZ1419 | 14.2 | 19.2 | 55 |

| HZ1520 | 15.3 | 20.3 | 55 |

Related Products